Decarbonisation of the cement industry

This info intends to draw your attention to the possibility and the need to combine your increased use of alternative fuels with optimization of your then smaller coal (incl. petcoke and lignite) handling and processing.

Many years of experience in the evaluation of the fire and explosion safety of existing coal handling and coal grinding systems in the cement industry are causing Coal Mill Safety Pte Ltd to state that almost nowhere on the world the protection of coal handling and coal grinding systems is correct. This is true for almost 100 % of the coal grinding systems in the cement industry.

That this situation can exist (and it exists since ever) is due to the fact that fires and explosions in coal handling and coal grinding systems of the cement industry are relatively rare, which leads to low awareness and to the result that no corrective actions are triggered. This means that the operations are accepting to wait for trouble.

The actuality of decarbonisation is further diverting the attention away from coal grinding.

Wherever, within the decarbonisation efforts of the cement industry, the focus is on the use or increased use of alternative fuels, changes in the storage, handling and processing of coal in then lower throughputs possibly will lead to smaller or bigger modifications of the technology used.

This then is the moment at which it makes sense to evaluate the existing conditions of coal handling and processing and to, along with the adjustment of the coal grinding throughput, correct the fire and explosion protection.

The correction of the fire and explosion protection possibly can be combined with simplification of the installed technology.

And the fire and explosion protection of the new alternative fuel systems can be made part of the consulting job done by Coal Mill Safety Pte Ltd.

Should this be the moment for you to pick up the matter, please send an email to info@coalmillsafety.com.

Transition From Coal to Alternative Fuels in Cement Production

What is happening in the cement industry is that everybody is thinking and talking about decarbonization, and one of the possibilities the cement industry has in that field is to reduce the use of coal and that they can do. There are all kinds of situations. There are all kinds of alternative fuels. Depending on where the cement plant is located, you will have to make a choice of the possibilities you have. And that means that the situation can end up in all kinds of ways. The replacement of coal in the fuel mix is going as far as roughly 70%. And, 70% of the coal can be replaced by alternative fuels of all kinds.

Listen to Podcast Transition From Coal to Alternative Fuels in Cement Production at Dust Safety Science

AFs drive improved fire and explosion protection

The introduction of alternative fuels (AFs) in a cement plant can often provide a good opportunity to improve fire and explosion protection systems. The availability of specialised knowledge is key to the successful completion of these projects.

Users of coal grinding systems are often unaware that they operate equipment that is not correctly protected against fire and dust explosions. During its fire and explosion protection evaluations in coal mills worldwide, Coal Mill Safety Pte Ltd has found the issue to be widespread, applying to larger and smaller cement producers, including those covered by ISO 9001 or similar QM certification. The issue spans the entire spectrum, from minor to major faults in protection, including non-existent protection. It is often the result of a lack of specialist knowledge by system suppliers, operators, certifiers and insurers, which then leads to a lack of hazard awareness. However, the number of fire or explosion- related incidents and the damage they inflict remains under the limit that would lead cement producers and their insurers to take corrective action. Therefore, this situation continues to exist.

Read more about AFs in the context of fire and explosion protection in our recent publication

Alternative solid fuels

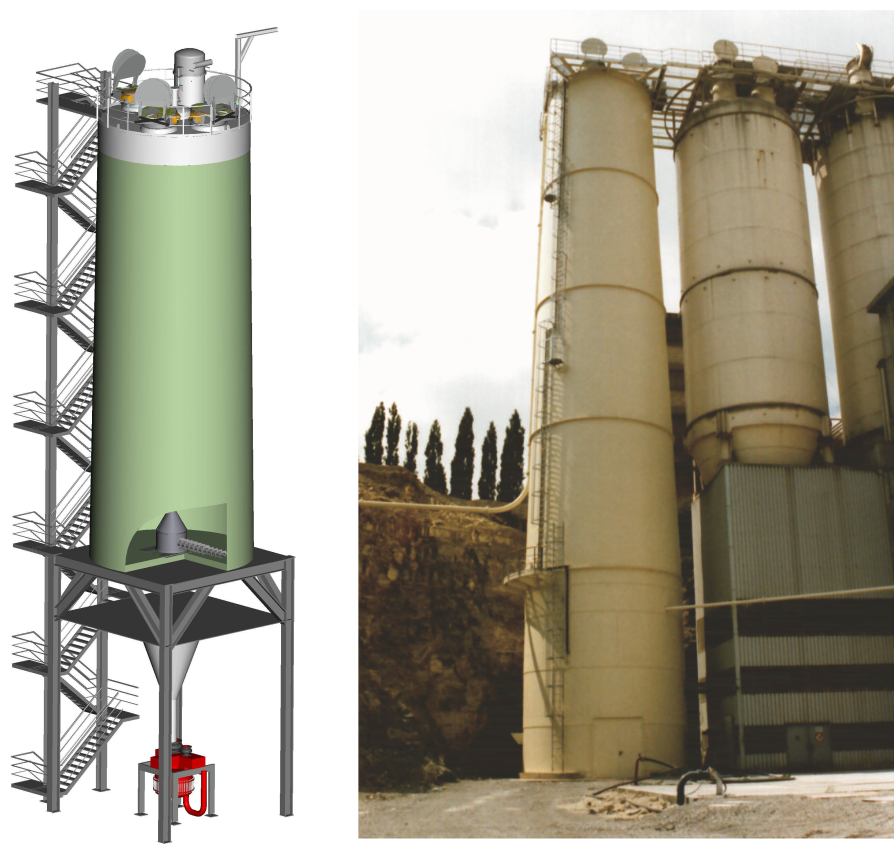

Many alternative solid fuels come with a dust content that will form an explosive atmosphere. Some alternative fuels can develop intensified oxidation (heating up) during silo storage. Here we have to look into silo storage and understand that the same protection as for silos for coal, lignite and petcoke has to be implemented.

A problem often is that silos supplied for the storage of alternative fuels come from companies with an agricultural background. The designs then often are incorrect in aspects like explosion pressure shock resistance and explosion venting, e. g. when non-self-reclosing explosion vents are installed, which makes effective firefighting impossible. Such silos simply are the wrong equipment and their correction can be difficult or impossible.